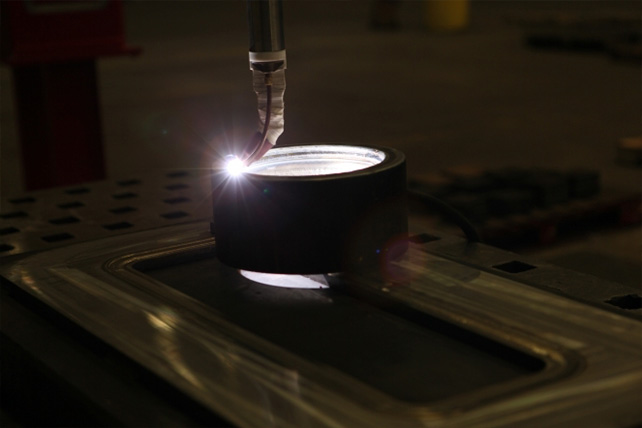

ELECTRON BEAM WELDING

When your application requires deep penetration and low distortion performed to precise specifications, our 110”x110”x110” New Generation Electron Beam Welding System can handle the job.

With this system, we can accommodate small to large parts that specifically require EB welding. The CNC controlled unit can weld dissimilar metals that require deep penetration into the material to create high purity welds with minimal distortion. The end result is a clean precise weld, each and every time.

Machine Specifications

- Internal chamber dimensions of 110”x110”x110”

- 1-1/4” thick vacuum chamber walls

- 30 kW computer controlled hard vacuum beam welder

- Internally mounted low voltage 60 kV moveable gun (60/60 type with high resolution optics)

- 30 kW power supply rated for 500 mA at 60 kV

- Constant voltage within +/- %1

Compatible Materials

- Steel Alloys

- Aluminum Alloys

- Stainless Steels

- Nickel-based Alloys

- Titanium

- Zirconium

Highlights

- Welding of dissimilar metals

- Deep penetration

- Clean welds

- High precision – CNC controlled

- High purity welds

- Low distortion – minimal heat used

FORMING

With one of the largest high tonnage press brakes in the state of Michigan, we can form large scale projects with up to 2000 tons of force. For smaller scale projects, our 250 ton press brake can bend metal up to ten feet in length.

STRAIGHTENING

With 1,000 tons of steel straightening power, we can straighten fabrications, bearings, bushings, steel and aluminum plating — from small, intricate components to multi-ton parts. Our multiple presses can form steel from 1/2 inch to ten inches thick.

MERRILL serves as the trusted fabrication partner for manufacturers in a wide variety of industries. Check out our latest high speed rail project here and see the MERRILL difference for yourself!

THE SOLUTIONS YOU NEED

MERRILL makes anything possible. From concept to completion and beyond, our top-to-bottom capabilities mean that we can design, build, test and deliver nearly every operation imaginable.

Solutions