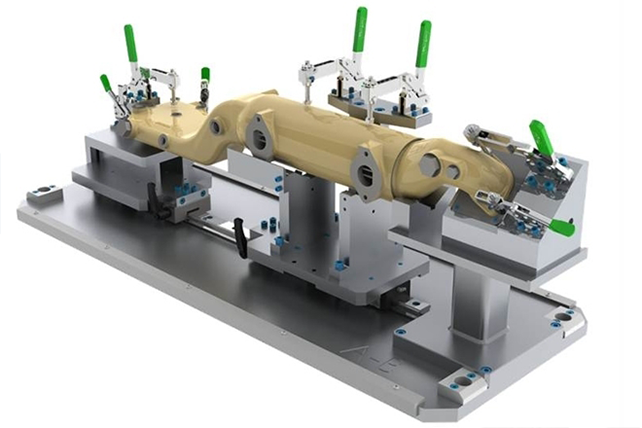

FINISHING. ASSEMBLING. TESTING.

MERRILL is the partner that can do it all for you. While we can easily handle standalone design and manufacturing projects, our ability to seamlessly integrate all of those capabilities down to finishing, assembly and testing is what truly adds value for our customers. From the everyday to the extraordinary, from concept to delivery, we will prototype, test, refine, produce, finish and deliver what you need. We do it all, so you don’t have to.

We thrive on this independence. And so will you.

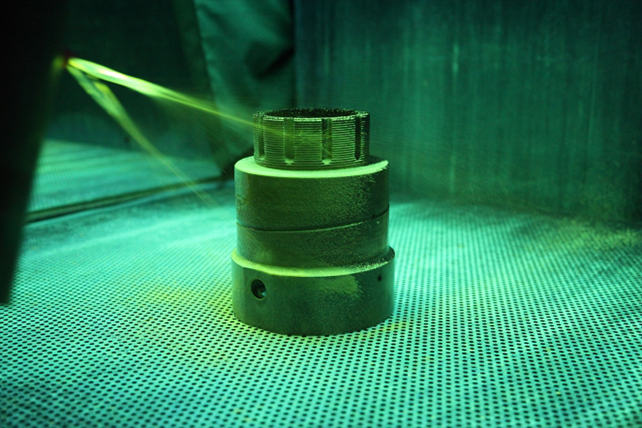

FINISHING

With three blasting chambers offering commercial, industrial and white blast finishes, we can provide blasting services for all metals in preparation for cleansing, painting and finishing. We work with many types of blasting media including aluminum oxide, garnet and glass bead.

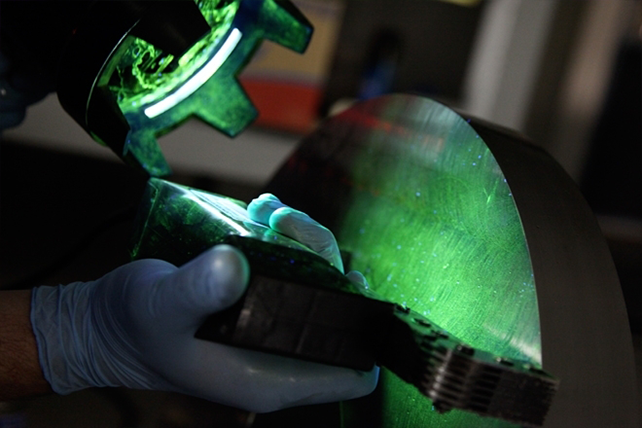

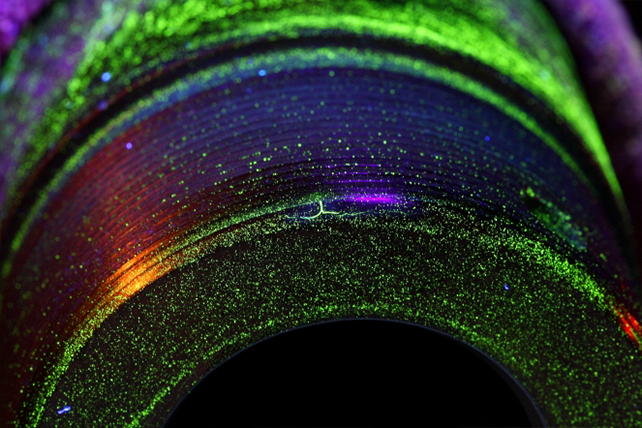

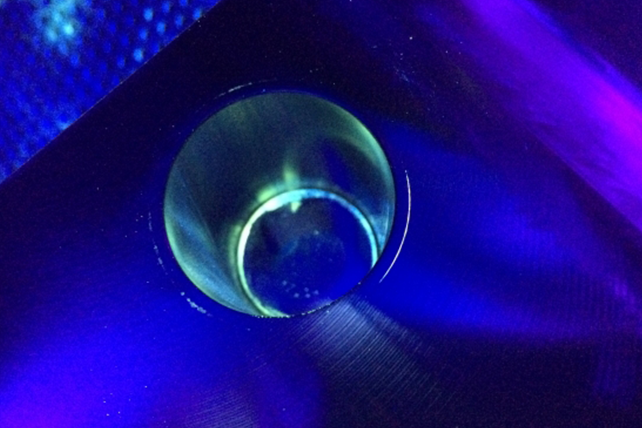

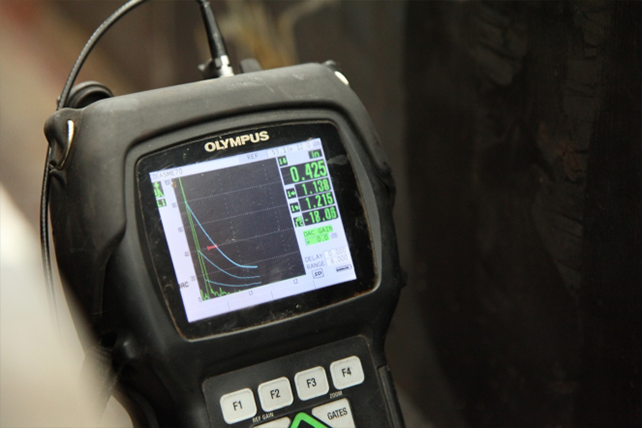

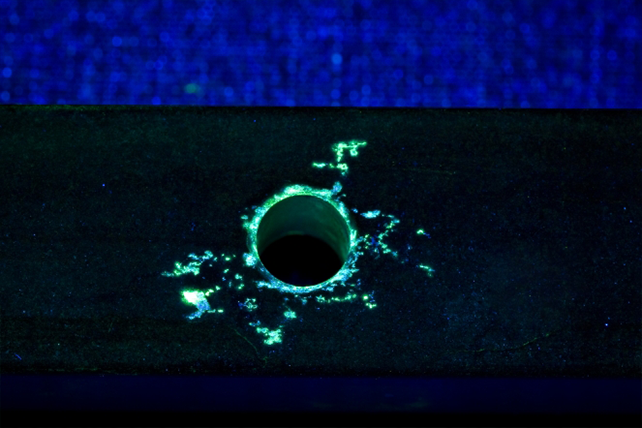

TESTING

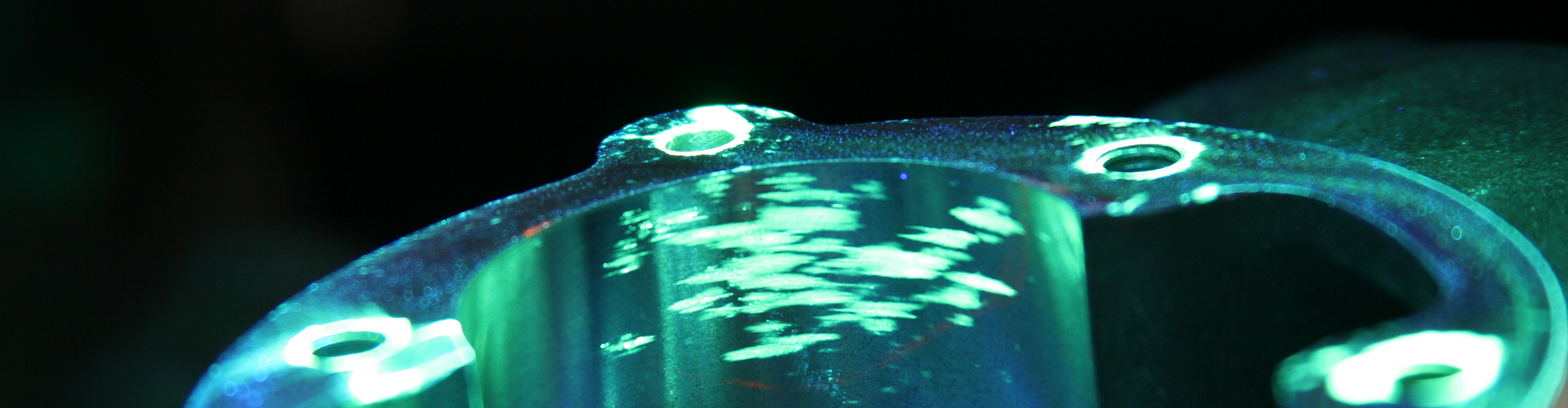

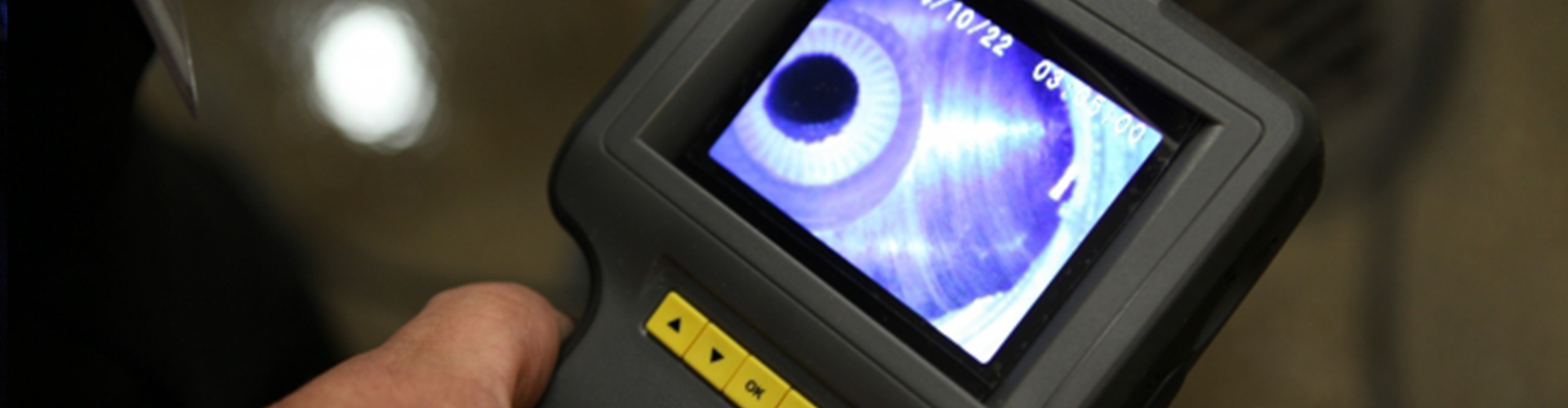

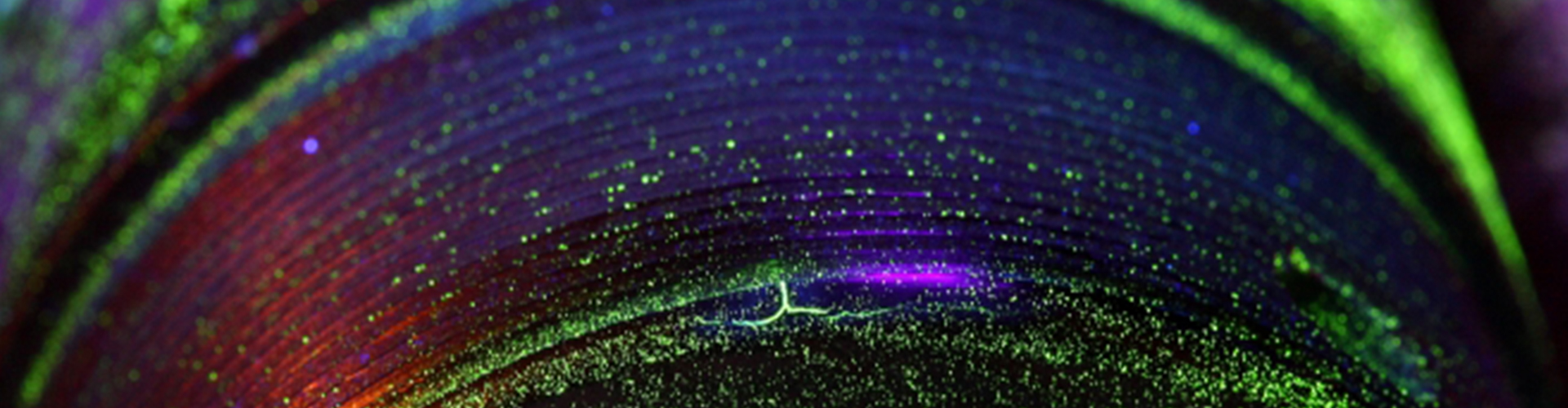

We inspect every product to ensure consistency, quality and traceability. We perform a wide range of visual and dimensional testing to OEM specifications including non-destructive testing (NDT), operational testing, real time performance testing and CMM inspection. NDT is performed to nationally-recognized standards including leak testing, magnetic pulse testing and fluorescent penetrant testing.

WORKING WITH THE WORLD'S LEADERS

For more than 50 years, MERRILL has been a trusted partner to world leaders across a wide range of industries.

Merrill Industries